Why is the port of the electronic connector to be plated?

The main replacement for electronic connectors is the terminal block. In the mid-to-high-end market, electronic connectors are less threatened by alternatives. This is mainly due to the fact that the electronic connectors themselves have evolved from the terminal blocks for convenient and fast error-free insertion and removal of cables. In the low-end market, electronic connectors are more threatened by alternatives. When the buyer is under pressure from the cost, the quality and cheap terminals are chosen.

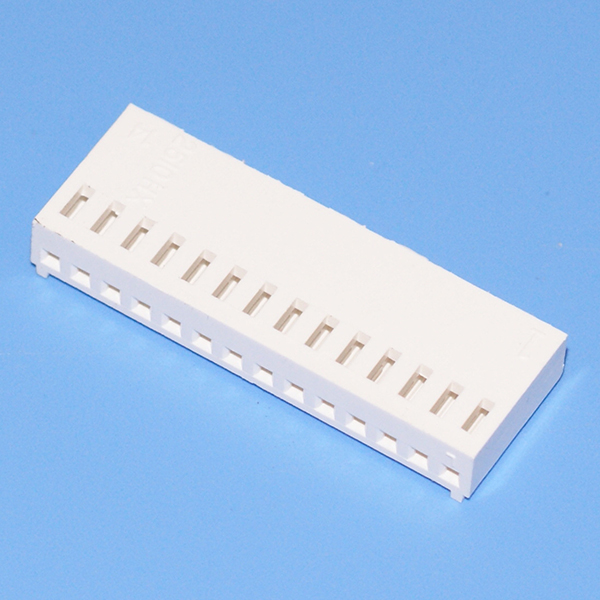

The metal connectors are metallized to prevent external factors such as contamination, diffusion of the substrate metal, and contact wear.

There are two types of coatings used in electronic connectors:

1. Characteristics of the use of precious metal coatings: To varying degrees, precious metal coatings (such as gold, palladium and their alloys) are essentially free of surface film. The metal contact that creates the interface for these coatings is relatively simple because it only requires movement of the accompanying surfaces of the contact surfaces during mating. Usually this is easy to implement. In order to maintain the stability of the contact interface impedance, the electronic connector design requires attention to maintain a precious metal coating on the contact surface.

2, the characteristics of the use of ordinary metal plating: ordinary metal plating, especially tin or tin alloy, its performance is naturally covered with an oxide film. The role of the tin contact coating is because the oxide is easily destroyed during the bonding, so that the metal contact is easily established.

The need for an electronic connector design is to ensure that the oxide film breaks when the electronic connector is mated, while ensuring that the contact interface is no longer oxidized during the life of the electrical connector. Reoxidation corrosion, in wear and corrosion, is the main performance degradation mechanism of tin contact coating. The silver contact plating is preferably treated as a common metal plating because the coating is susceptible to corrosion by sulfides and chlorides. The nickel plating is usually regarded as a common metal because of the formation of the gas valve.

The above is why the port of the electronic connector should be shared and why, if the industry's small partners do not understand, or want to know more information, you can contact us Dongguan Guanhang Electronics Co., Ltd.!

Latest articles

- Guanhang Electronics tells you

- Why can't we standardize the d

- How to choose a data line whol

- What is the difference between

- How to choose the right data l

- What are the contraindications

- How to distinguish USB data ca

- 3.5mm headphone jack structure

- Design specifications for elec

- Explanation of common terms in

- What is the upper and lower fi

- Why is the port of the electro

- FPC connector package size

- What is the pre-production ele

- Future electronic connectors w